S69R Mast Section For Tower Crane Masts

- ZCJJ

- China

- 10days

- 50pcs

Sekondi-Takoradi Tower crane, Sekondi Tower crane,

Cape Coast Tower crane, Cape Coast Tower crane,

Koforidua Tower crane, Koforidua Tower crane,

Products Specification

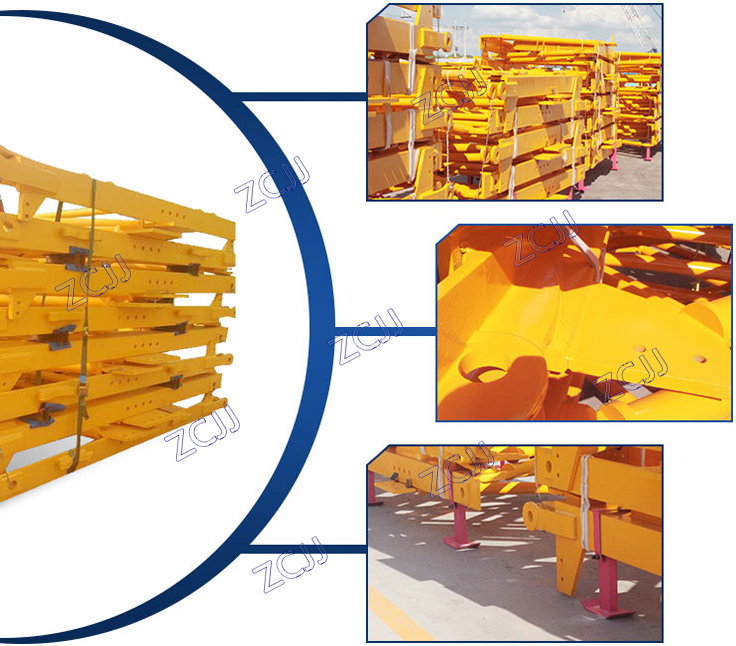

Type , Model: S69R Mast Section For Tower Crane Masts

Size: 2mx2mx3m

Materials: Q345B

Within: Pins, bolts, Ladder, Platform

Process: Blasting derusting,

Painting: Under painting , Middle painting, Surface painting.

Our factory produce and supply almost all famous brand tower crane :Mast section, Anchor Frame, Fixing angle ,Adaptor and so on as good quality and price.

S69R Mast Section For Tower Crane Masts

Tower Crane Knowledge sharing:

Four Important Points for Safe Operation of Heavy Tower Suspension

Tower crane is a large lifting equipment, its safety can not be underestimated. There are not a few tower hanging accidents caused by improper operation of Tower lifting.

The operation of heavy tower crane should strictly observe the safety operation rules of tower crane.

1. There shall be sufficient working space for the lifting of the tower, no obstacles within the lifting and landing radius of the lifting boom, and adequate lighting equipment for night operations.

2. Before operation, you must have a comprehensive understanding of the surrounding environment, driving roads, overhead wires, buildings, and the weight and distribution of components at the work site.

3. Safety protection devices such as variable-amplitude indicators, torque limiters, and various stroke limiters for tower cranes must be complete, sensitive, and reliable, and must not be arbitrarily adjusted and removed

It is strictly forbidden to use the limiting device instead of the operating mechanism for downtime.

S69R Mast Section For Tower Crane Masts

4. It is forbidden to lift some overloaded objects. It is strictly forbidden to use tower cranes for sloping, sloping, and lifting weights that are buried or condensed on the ground. Concrete components on the construction site must be fully loose before lifting.

The performance and quality of the lifting mechanism directly reflect the performance of the whole machine

Tower lifting is an indispensable bulk goods handling equipment in the construction, transportation and logistics industries, and the part that makes the tower lifting up is the lifting and lifting mechanism of the tower.

Its performance and quality directly reflect the performance of the tower lifting. At the same time, it is also the most powerful mechanism in the three major mechanisms of Tower suspension, which consists mainly of motors, decelerators, brakes, and racks.

First of all, let us understand the motor part of the lifting mechanism-the type of motor used in the tower crane and the good or bad determine the lifting performance of the tower crane.

At present, the widely used lifting motors are: multi-speed motor, winding motor, frequency converter motor. Its performance and price are increased one by one, and the same type of different manufacturers produce different processes, and their quality and price vary greatly.

Immediately afterwards, it is an indispensable reducer in the tower crane parts. At present, the tower crane uses a multi-stage cylindrical gear reducer.

However, due to the fierce competition in the market, the business concepts of different enterprises are different, and the production techniques used are different. Its quality and price vary greatly.

As far as I know, some gear reducers do not do heat treatment and surface treatment at all to meet the low prices of the market.

As a result, the performance of the product is not guaranteed at all, the life span is greatly reduced, and there is a lot of noise soon. situation.

In addition, the reliability of the tower crane brake in the lifting mechanism also directly affects the safety performance of the tower crane. The selected manufacturers deserve attention.

S69R Mast Section For Tower Crane Masts

The frame is similar to the metal structure of the tower crane. Its main role is to provide physical support for the lifting mechanism. Whether its structure form and material selection are reasonable is also a problem that needs attention.

The Three Principles of Selecting the Standard Festival of the Staircase Accessories

As one of the basic components of tower crane, the tower crane standard festival plays an indispensable and important role in tower crane structure. A section is connected together to form the main skeleton of the tower crane.

A good standard section can not only improve the flexibility and efficiency of the machinery, but also play a key role in avoiding the collapse of the tower crane. Therefore, the selection of the tower hanging standard festival is of great significance.

Many tower hoisting companies and second-hand tower hoisting rental companies often choose unsatisfactory standard festivals because they are not familiar with the "market".

First of all, when selecting the standard festival for tower hoists, we should look at the security labels that have been affixed, or their own security marks that have been affixed by regular manufacturers.

If not, such relatively coarse and unreliable in quality and can not withstand long-term use. So do not covet cheap, durable is the hard truth.

Secondly, when checking the sample, we should look at whether the standard section of the tower crane is smooth and delicate. If so, it is generally more sophisticated and the processing and production are relatively in place.

The standard section of the tower crane is not accurate.

Third, in the near view of the standard section of the tower hanging, it should also be seen whether the connection is good, whether the joints are flexible, lubricated, if rust occurs, or the connections are relatively slow, such a standard section is best not to buy.

Because most tower hoists have limited maintenance times, and the environment where the sun is soaked in rain and salt and alkali(such as cement) corrosion is serious, the tower hoist standard festival must face many tests.

Therefore, when selecting the standard festival, only careful and careful can really achieve good results.

S69R Mast Section For Tower Crane Masts

Tower Hang Accessories-Installation Steps and Attention of Balance Arm

Among the many components of the tower crane, the role of the tower crane balance arm is mainly to provide reverse torque for the lifting arm, so as to ensure the balance of the body in the lifting process.

It is one of the important tower crane accessories.

In most cases, the tower crane balance arm is a structure formed by welding the I-steel and corner steel groups. It is divided into two sections and connected by an earplate pin shaft.

The tower crane balance arm is equipped with railings and aisles, and the tail is equipped with a working platform. One end of the tower crane balance arm is connected to the rotating tower body with two special axles, and the other end is combined with a rigid pull rod connected to the tower cap.

The tail is equipped with a balanced weight and lifting mechanism. The lifting mechanism itself has an independent base, with four pins. The shaft is balanced on the tower crane balance arm. The weight of the balance weight varies with the length of the boom.

In the process of installing the balance arm of the tower crane, the two balance arms should be assembled on the ground first, and the lifting mechanism, the electric control box, and the resistance essence should be put together.

The balance arm lever is mounted on the balance arm and should be well connected. The rotary mechanism is connected to the temporary power supply, and the above part of the rotary support is rotated to the position where the balance arm is easily installed.

Immediately thereafter, the tower crane construction personnel should hang up the balance arm(the balance arm is equipped with 4 mounting hanging ears), and use the pin shaft to fix the balance arm and the rotary tower body.

S69R Mast Section For Tower Crane Masts

The balance arm is gradually raised to the appropriate position, so that the balance arm's pull rod and the balance pipe's pull rod on the top of the tower are connected with the pin wheel, and the pin shaft is closed and the opening pin is opened.

Finally, the balance arm is slowly lowered and then hoisted to reinstall the balance on the back of the balance arm to the position closest to the top of the tower.

YONGMAO STT983 Mast section

YONGMAO STT753 Mast section

YONGMAO STT553 Mast section

YONGMAO STT403 Mast section

YONGMAO STT293 Mast section

YONGMAO STT253 Mast section

YONGMAO STT200 Mast section

YONGMAO ST80/238 Mast section

YONGMAO ST80/160 Mast section

YONGMAO ST80/116 Mast section

YONGMAO ST80/75 Mast section

YONGMAO ST80/60 Mast section

YONGMAO ST80/31 Mast section

YONGMAO ST70/50 Mast section

YONGMAO ST75/32 Mast section

YONGMAO ST70/32 Mast section

YONGMAO STL720 Mast section

YONGMAO STL660 Mast section

YONGMAO STL530 Mast section

YONGMAO STL420 Mast section

YONGMAO STL420A Mast section

YONGMAO STL330 Mast section

YONGMAO STL230 Mast section

YONGMAO STL203C Mast section

YONGMAO STL180 Mast section

SYM S315K16 Mast section

SYM S315K18 Mast section

SYM S315K16B(QTZ315) Mast section

SYM K50/50(QTZ450) Mast section

SYM K50/50B(QTZ450) Mast section

SYM K50/50C(QTZ450) Mast section

SYM K50/70(QTZ500) Mast section

SYM K50/70B(QTZ500) Mast section

SYM S450L25(QTZ450) Mast section

SYM S450L25B(QTZ450) Mast section

SYM S560K25(QTZ560) Mast section

SYM S560K25B(QTZ560) Mast section

SYM S650H24(QTZ500) Mast section

SYM S650M25(QTZ650) Mast section

SYM S650M25B(QTZ650) Mast section

SYM S650M32(QTZ650) Mast section

SYM S650M32B(QTZ650) Mast section

SCM C3208 Mast section

SCM D650 Mast section

SCM D360 Mast section

SCM D320 Mast section

SCM D230 Mast section

SCM D160 Mast section

SCM D120 Mast section

SCM D120 (A) Mast section

SCM D90 Mast section

SCM D60 Mast section

SCM P2200 Mast section

SCM P1200 Mast section

SCM P900 Mast section

SCM P600 Mast section

SCM P360 Mast section

SCM P8042 Mast section

SCM P8030 Mast section

SCM P7527 Mast section