L69B2 Mast Section For Tower Crane Masts

- ZCJJ

- China

- 10days

- 50pcs

Béja Tower crane, Bizerte Tower crane,

Ben Arous Tower crane, Jendouba Tower crane,

Médenine Tower crane, Manouba Tower crane,

Products Specification

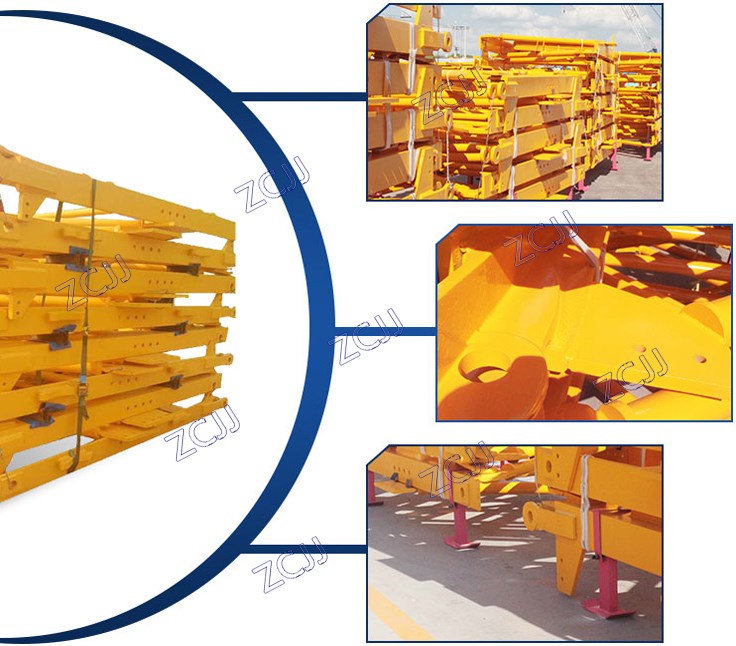

Type , Model: L69B2 Mast Section For Tower Crane Masts

Size: 2mx2mx3m

Materials: Q345B

Within: Pins, bolts, Ladder, Platform

Process: Blasting derusting,

Painting: Under painting , Middle painting, Surface painting.

Our factory produce and supply almost all famous brand tower crane :Mast section, Anchor Frame, Fixing angle ,Adaptor and so on as good quality and price.

L69B2 Mast Section For Tower Crane Masts

Tower Crane Knowledge sharing:

The balance arm of the tower crane is mainly to provide reverse torque for the lifting arm to ensure the balance of the body.

Among the many components of the tower crane, the role of the tower crane balance arm is mainly to provide reverse torque for the lifting arm.

In most cases, the tower crane balance arm is a structure made of industrial steel and angle steel groups, divided into two sections. Connected with an earplate pin shaft, Thus to ensure the balance of the body in the lifting process, is one of the important tower hanging accessories.

In the process of installing the balance arm of the tower crane, the two balance arms should be assembled on the ground first, and the lifting mechanism, the electric control box, and the resistance essence should be put together.

The balance arm lever is mounted on the balance arm and should be well connected. The rotary mechanism is connected to the temporary power supply, and the above part of the rotary support is rotated to the position where the balance arm is easily installed.

Immediately thereafter, the tower crane construction personnel should hang up the balance arm, and use the pin shaft to fix the balance arm and the rotary tower body.

The balance arm is gradually raised to the appropriate position, so that the balance arm's pull rod and the balance pipe's pull rod on the top of the tower are connected with the pin wheel, and the pin shaft is closed and the opening pin is opened.

L69B2 Mast Section For Tower Crane Masts

Finally, the balance arm is slowly lowered and then hoisted to reinstall the balance on the back of the balance arm to the position closest to the top of the tower.

There are railings and passages on the balance arm of the tower crane, and a working platform is set up at the tail. One end of the balance arm of the tower crane is connected to the rotating tower body with two special axles, and the other end is combined with a rigid pull rod and a tower cap.

The tail is equipped with a balance weight. And lifting mechanism, The lifting mechanism itself has an independent base and is balanced on the balance arm of the tower crane with four pins. The weight of the balance weight changes with the length of the crane.

The performance and quality of the lifting mechanism directly reflect the performance of the whole machine

Tower lifting is a necessary lifting equipment in the construction, transportation, and logistics industries, and the part of the tower lifting lifting weight is the tower lifting lifting mechanism, and its performance and quality directly reflect the performance of the tower lifting.

At the same time, it is also the most powerful mechanism in the three major structures of the tower crane. It mainly consists of motors, speed reducers, brakes, and racks.

First of all, let us understand the motor parts in the lifting mechanism -- the type of motor used in the tower crane and the lifting performance of the long arm crane for good or bad voting.

L69B2 Mast Section For Tower Crane Masts

So far, the lifting Motors widely considered suitable for use are: multi-speed Motors, winding Motors, Variable frequency motor. Its performance and price are increased one by one, the same type of product is not the same manufacturer's production process, its quality and price difference is also very large.

The tight continuation is a speed reducer that can not be absent from the tower crane parts. Until now, the tower crane has considered it appropriate to use a multi-stage cylindrical gear speed reducer.

However, because the market competition is very tight, the company's management philosophy is different. The production process that is considered suitable and used is not the same, and its quality and price are very different.

According to my understanding, in order to meet the low demand of the market, some speed reduction machine factories do not do heat disposal and external disposal at all.

As a result, the performance of the products is not guaranteed at all, and the survival period is greatly reduced. It quickly revealed a very noisy situation.In addition to this, the reliability of the tower crane brake in the lifting mechanism also directly affects the safety performance of the tower long-arm crane. The selected factory value should be concerned. The metal structure of the frame is roughly similar to that of the tower long-arm crane.

The main effect is to provide physical support for the lifting mechanism. Whether its structure and material selection are reasonable is also a problem for demand.

L69B2 Mast Section For Tower Crane Masts

Strict implementation of scrap standards for the repair and maintenance of metal structures for tower cranes

Repair and maintenance of the metal structure parts of the tower crane: The main structural parts should be inspected for metal fatigue strength, weld cracks, structural deformation, damage, etc.

the key weld parts of the main structural parts and the parent materials in the welding heat affected areas should be inspected. If an exception is found, it should be processed. Strictly implement the scrap standard of steel structure parts for tower lifting.

Repair and maintenance of the metal structure of the tower crane shall be carried out in accordance with the following procedures:

Tower lifting demolition:

When a project is completed and the tower crane is dismantled, the engineering technicians and professional maintenance personnel should conduct detailed inspections and make good records.

In the course of transportation, every effort should be made to prevent structural deformation and collision damage. Brush paint every six months to one year. Rust, oil and other dirt on the metal surface should be removed before painting.

Tower crane installation:

Safety acceptance work of tower crane. Now, we must classify and summarize the relevant items before installing the tower crane. First, we must accurately and reasonably locate the floor plan and elevation map provided by the project department. We must not only be able to facilitate installation, but also be able to dismantle smoothly.

L69B2 Mast Section For Tower Crane Masts

The wall spacing should be reasonable. The installation of multiple tower hoists should consider the minimum interference with another tower hoist within the radius of the tower hoist.

According to the geological report provided by the project department, it is necessary to judge whether the ground endurance of the tower crane installation position meets the requirements of the manual, and if it does not meet the requirements.

It should work out a feasible plan together with the company's technical department to make pile reinforcement treatment or increase the foundation, and provide calculation basis

Then provide the base map of the tower to the project department and construct it according to the plan.

The base steel bar and concrete of tower crane should have quality insurance policy, concrete test block report, urgent check list. According to the basic diagram, the reinforcement shall not be arbitrarily deleted. And shall be valid by the signatory of the supervision department.

After the tower crane is installed, it must be well observed, measured, recorded, and archived in order to correct the problem in time and ensure that the vertical degree of the tower crane is within 3 inches.

Routine inspection:

The tower crane shall undergo a daily inspection every 80 hours of work. The tower crane driver should check the fastening condition of the bolts at each connection site when handing over the shift.

If there is any loosening, it should be fastened in time. When there is an abnormal sound in the tower crane, or there is a mistake in operation,

YONGMAO STT983 Mast section

YONGMAO STT753 Mast section

YONGMAO STT553 Mast section

YONGMAO STT403 Mast section

YONGMAO STT293 Mast section

YONGMAO STT253 Mast section

YONGMAO STT200 Mast section

YONGMAO ST80/238 Mast section

YONGMAO ST80/160 Mast section

YONGMAO ST80/116 Mast section

YONGMAO ST80/75 Mast section

YONGMAO ST80/60 Mast section

YONGMAO ST80/31 Mast section

YONGMAO ST70/50 Mast section

YONGMAO ST75/32 Mast section

YONGMAO ST70/32 Mast section

YONGMAO STL720 Mast section

YONGMAO STL660 Mast section

YONGMAO STL530 Mast section

YONGMAO STL420 Mast section

YONGMAO STL420A Mast section

YONGMAO STL330 Mast section

YONGMAO STL230 Mast section

YONGMAO STL203C Mast section

YONGMAO STL180 Mast section

SYM S315K16 Mast section

SYM S315K18 Mast section

SYM S315K16B(QTZ315) Mast section

SYM K50/50(QTZ450) Mast section

SYM K50/50B(QTZ450) Mast section

SYM K50/50C(QTZ450) Mast section

SYM K50/70(QTZ500) Mast section

SYM K50/70B(QTZ500) Mast section

SYM S450L25(QTZ450) Mast section

SYM S450L25B(QTZ450) Mast section

SYM S560K25(QTZ560) Mast section

SYM S560K25B(QTZ560) Mast section

SYM S650H24(QTZ500) Mast section

SYM S650M25(QTZ650) Mast section

SYM S650M25B(QTZ650) Mast section

SYM S650M32(QTZ650) Mast section

SYM S650M32B(QTZ650) Mast section

SCM C3208 Mast section

SCM D650 Mast section

SCM D360 Mast section

SCM D320 Mast section

SCM D230 Mast section

SCM D160 Mast section

SCM D120 Mast section

SCM D120 (A) Mast section

SCM D90 Mast section

SCM D60 Mast section

SCM P2200 Mast section

SCM P1200 Mast section

SCM P900 Mast section

SCM P600 Mast section

SCM P360 Mast section

SCM P8042 Mast section

SCM P8030 Mast section

SCM P7527 Mast section