MC235B Tower Crane Lease Rent Hire

- Famous Global

- Global

- 5 to 50days

- as u need units

French Polynesia used Tower Crane , Pitcairn Island used Tower Crane,

MC235B Tower Crane Lease Rent Hire

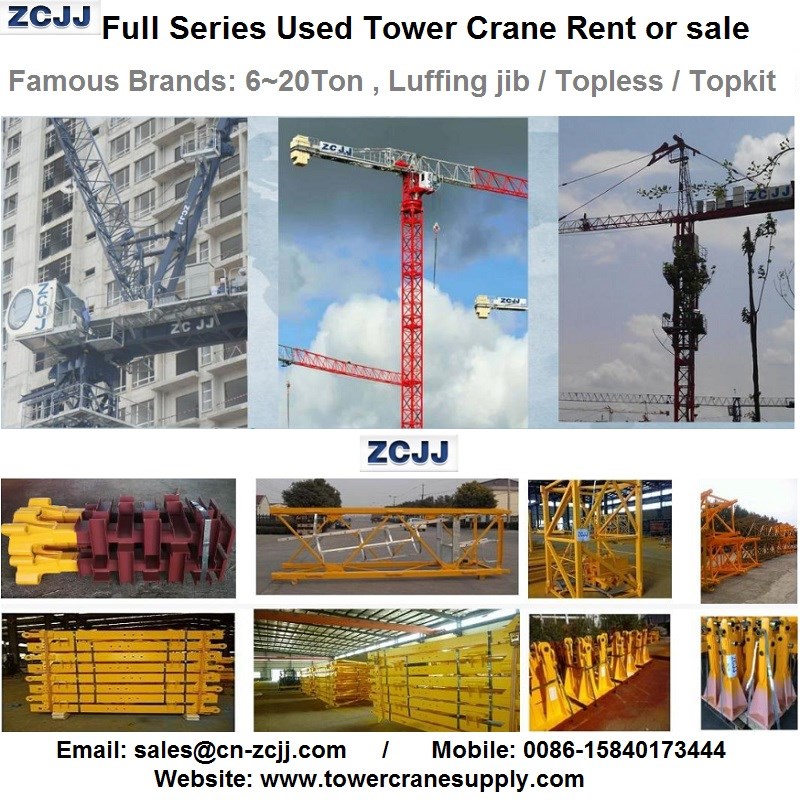

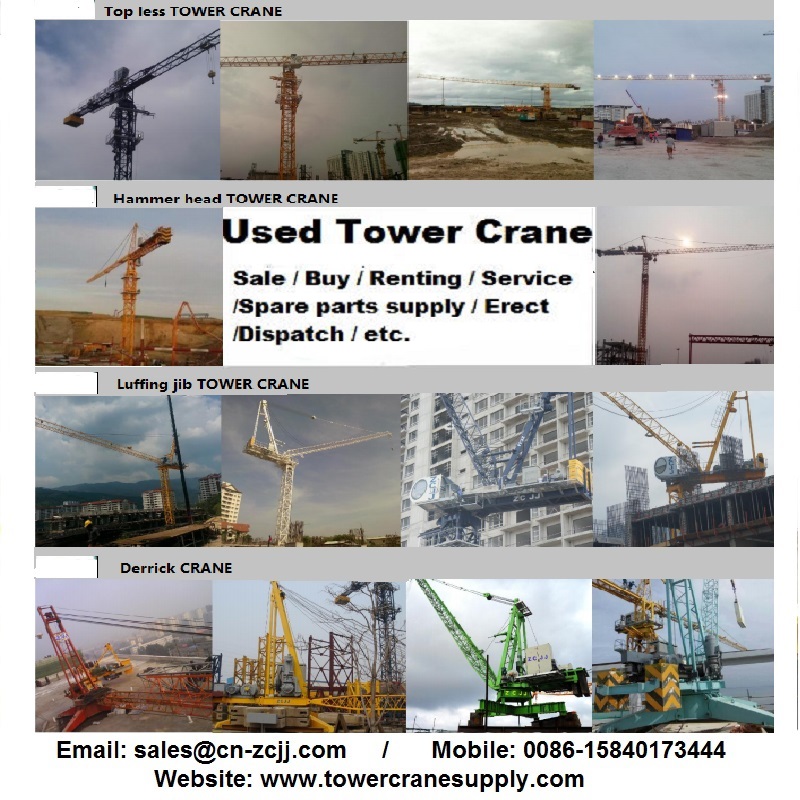

Series , Luffing jib Crane, Topkit tower crane, Hammer head tower crane, Topless tower crane, Flat top tower crane,

Model,

Jib length, m

Max load, Ton

Tip load, Ton

Type, Stationary , Inter climbing ,Travelling,

And other Famous brand, Model , Depend on the brand , Model Ability , Year , Height and etc u want.

We have large units store. From 6Ton to 20Ton. Store and Service all over the world.

Mean time , We supply all the Spare Parts U may need as follow,

Masts Section , Anchor Frame, Collar ,Tie , Fixing angle , Cabin, Hoist mech. Trolley mech. Luffing Mech. Slewing Mech. Pulley and etc.

MC235B Tower Crane Lease Rent Hire

Tower Crane Knowledge sharing:

When carrying on the inspection to the tower crane, often can discover the tower body standard section connection bolt to become loose the situation, some nut hand all can twist into, raises gently with the hand, also can feel the bolt the axial direction to move, this indicated the bolt has become loose to the point which does not have the force.

Then, what is the cause of the tower crane standard joint bolt loose situation? In this paper, according to the tower crane standard joint bolt loose reasons, hazards and preventive measures to explain.

MC235B Tower Crane Lease Rent Hire

Reasons for loose connection bolts of standard section of tower crane

What reason causes tower crane standard joint bolt to become loose? We first analyze the force characteristics of the tower body. The force of the tower body can be simplified as bending moment M perpendicular to the horizontal plane, torque T on the horizontal plane, axial pressure N, and horizontal force F, among which M and T have a great influence on bolt looseness.

When lifting the weight by the boom, M is positive and M is negative after dropping the weight. T is positive when turning on and negative when turning on.

MC235B Tower Crane Lease Rent Hire

In normal operation, the tower crane frequently lifts and drops the heavy objects, and the crane arm starts and brakes repeatedly, which makes the tower body bear the bending moment and torque with alternating and frequent changes of positive and negative values.

As a result, the force on the standard joint bolts keeps changing repeatedly, which is the root cause of the bolt loosening. The working characteristics of the tower crane determine the force characteristics of the standard joint bolts, which is insurmountable. For this reason, all the tower crane manufacturers adopt high strength bolts to connect the standard section of the tower crane.

The specifications of the tower

MC235B Tower Crane Lease Rent Hire

crane and the operating instructions of each tower crane manufacturer all put forward requirements for the installation of this kind of bolt connection, which requires the application of pre-tightening force during installation. Different pre-tightening force values are given for connection bolts of different specifications.

For example, for the commonly used 8.8 class M24 bolts, the pre-tightening force is 155KN. In order to accurately apply the pre-tightening force, it is necessary to calculate the tightening torque acting on the bolt according to the torque coefficient of high-strength bolts. For the above 8.8-class M24 bolts, the theoretical pre-tightening torque is about 700N·m. At present, the installation of tower cranes in chengdu is almost entirely done by tightening bolts with the experience of operators.

Many operators do not even have the concept of preload and theoretical preload torque, let alone the torque to control the bolt preload. In addition, tightening the connection bolts of standard joints is performed at high altitude, and the operating conditions are not good. If the actual pre-tightening torque is applied to 500N, the labor intensity of workers will be greatly increased, and it is not easy to directly twist the pre-tightening torque to meet the requirements by manpower.

It can be seen that the pre-tightening force of the bolts of the actual installation of the tower crane can hardly meet the requirements of the pre-tightening force, which is the important reason for the bolt looseness.

MC235B Tower Crane Lease Rent Hire

In addition, when the tower crane jacking up and adding nodes, the contact surface of the standard joint on the boom side is pulled, and the contact surface of the standard joint on the balance boom side is compressed. Under the action of the same tightening torque, the pre-tightening force in the bolts on both sides is equal.

Rotate when the tower crane, crane jib direction changes, the tower section compression of contact surface tension situation change, bolt the stress change is very big, especially has returned to the boom and jack-up section in the opposite direction, the crane jib lateral section connection interface from tension to compression, the tensile strength of the bolt are greatly reduced.

MC235B Tower Crane Lease Rent Hire

Especially when the pre-tightening force less than too much, correct value is likely to be without the pre-tightening force, this is another important reason for the bolt looseness.

There are some units, the tower crane management is very strict, originally with a double nut bolt, only installed a nut when the installation, bolt connection of the original anti-loose measures no, and in the alternating change of frequent load work, it is easy to loose.

In addition, the management of the tower crane crew is not in place, and the operators fail to inspect and tighten the bolts. Once the bolts become loose, they fail to timely find the fastening, which will worsen the stress situation of other bolts and cause a large number of bolts to become loose.

Danger of loose connecting bolt of standard section of tower crane

The tower body is like the "trunk" of the tower crane, playing the role of supporting the upper working parts, and mainly bearing the axial pressure, horizontal force, bending moment and torque from the top working parts. The bolt looseness mentioned above refers to the tower body that is connected by bolt sleeve between standard joints.

At present, most small and medium-sized tower cranes (60t·m and below) of tower crane manufacturers adopt this connection form, and the bolts are all high-strength bolts.

The standard connecting bolt of tower body is not allowed to come loose, and its harm is very serious. Article 2.2.2.2 of safety regulations for construction tower cranes (gb5144-2006) expressly states that "connection bolts must be tightened with torque wrenches or special wrenches according to assembly technical requirements", and the same requirement is made in the operation manual of such tower cranes.

TOWER CRANE USED

LIEBHERR TOWER CRANE USED

TEREX TOWER CRANE USED

SYM TOWER CRANE USED

SCM TOWER CRANE USED

YONGMAO TOWER CRANE USED

COMEDIL TOWER CRANE USED