R80A Bases Fixing Angle Tower Crane

- ZCJJ

- China

- 5days

- 20sets

Kuwait City Tower crane, Jahra Tower crane,

Fairvano Tower crane, Havalli Tower crane,

Mubarak Al-Kabeer Tower crane, Al Ahmadi Tower crane

Beirut Tower crane, Tripoli Tower crane

Products Specification

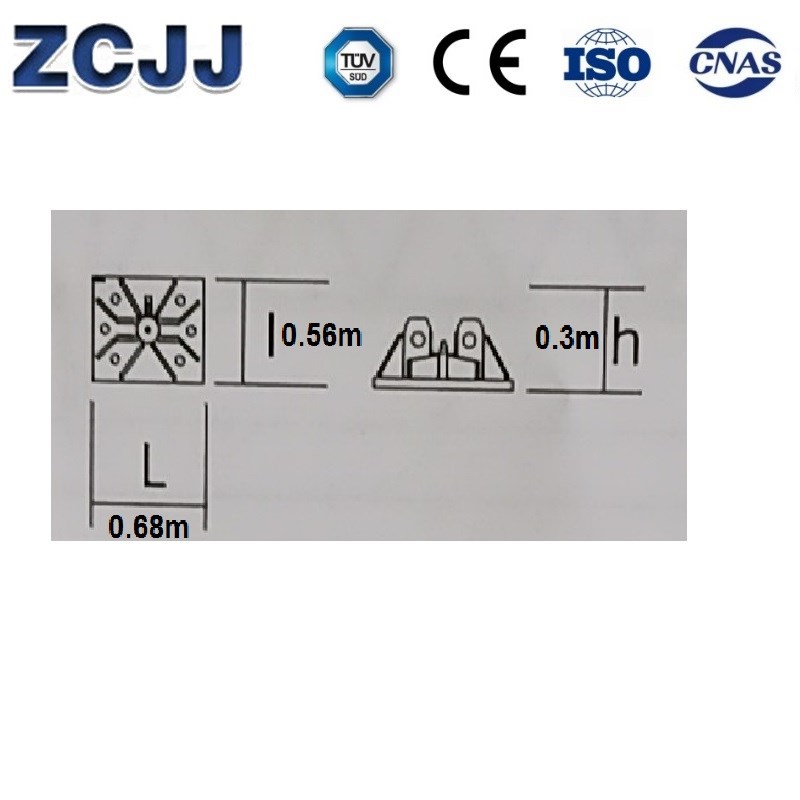

Type , Model: R80A Bases Fixing Angle Tower Crane

Size: 2.9M

Use for : R87 Mast R86 Mast , 2.9x2.9x5.98m

Materials: Q345B

Process: Blasting derusting,

Painting: Under painting , Middle painting, Surface painting.

Our factory produce and supply almost all famous brand tower crane :Mast section, Anchor Frame, Fixing angle ,Adaptor and so on as good quality and price.

R80A Bases Fixing Angle Tower Crane

Tower Crane Knowledge sharing:

Special scheme for tower crane installation safety: installation requirements, preparation, jacking and operation

18, the operation site should be prohibited from the entry and exit of miscellaneous personnel, street operations, to take protective measures.

Vi. Tower crane jacking safety matters

1. Note before jacking:

(1) before jacking, put the standard sections added under the big arm one by one.

(2) adjust the clearance between the guide wheel of the climbing frame and the tower body to 2-3mm.

(3) the length of the loosened cable is slightly larger than the total climbing height.

(4) before the oil cylinder starts to move, it must check whether the jacking beam is in the correct position.

(5) test operation shall be carried out before jacking up, and lifting tower or lowering tower shall be carried out after normal operation.

R80A Bases Fixing Angle Tower Crane

2. Attention shall be paid during jacking

(1) before the oil cylinder starts to move, it is necessary to check whether the jacking beam is in the correct position and whether the upper part of the jacking is in the balance position; otherwise, it should be adjusted to make the tower balanced on both sides. adjustment method adjust the position of the trolley, so that the upper center of gravity of the tower crane falls on the 4 position of the jacking beam.

In actual operation, it is observed that the four-angle guide wheel on the climbing frame is both an ideal position when it is basically separated from the standard tangential rod of the tower body.

(2) in the climbing operation, the lifting arm cannot rotate, and the oil cylinder is always under the specified pressure.

(3) only individual movements are allowed. Climbing and other movements are strictly prohibited.

(4) when the climbing sleeve is separated from the standard section of the tower body, it is forbidden to lift heavy objects.

R80A Bases Fixing Angle Tower Crane

(5) in the process of jacking, the lifting boom should be kept in a straight forward position.

(6) during jacking, the slewing mechanism must be in an effective braking state.

(7) in case of continuous addition of sections, all high-strength bolts between the standard section of the tower body and the lower support shall be tightened before the next standard section is lifted by the tower body itself after each section is added.

(8) the standard section added must be aligned with the standard section of the existing tower body.

3. Attention shall be paid after jacking

(1) after adding joints, rotate the boom to different angles to check the tightening situation of high-strength bolts in each joint of tower body section, especially the tightening situation of connecting bolts between support and tower body.

(2) when the tower crane is finished adding joints, the climbing frame shall be lowered to the bottom of the tower body and fixed to lower the center of gravity of the whole tower body and reduce the windward area.

(3) after the tower crane is jointed, put the operating handle at the zero position and cut off the power supply of the hydraulic system.

4. Overall safety matters

(1) no jacking up is allowed if the wind force is greater than level 4.

(2) all operators shall hold valid certificates.

(3) strictly abide by the safe operation procedures and the process and technology disclosure specified in the manual.

(4) all operators must wear safety helmet, non-slip shoes and safety belt when necessary.

(5) the tools and bolts used in the operation should be placed in a safe and reliable position to prevent falling and injuring people.

R80A Bases Fixing Angle Tower Crane

Vii. Safe operation plan of tower crane

1. Check and power supply

Before starting the machine, check the power supply condition of the site, whether the grounding of the tower crane is good, whether the cable connector is in reliable contact, whether there is damage or electricity leakage on the cable.

After checking and confirming that it meets the requirements, the power can be switched on. Close the iron shell switch power supply at the bottom of the tower crane, close the air switch in the operating room, connect the power supply to the main circuit and each control circuit.

The power indicator light is on. The air switch is usually closed when the driver is ready to operate. It is strictly prohibited to pile things in the driver's room, which prevents the driver from quickly pulling the air switch to cut off the power in an emergency. When the driver leaves, the air switch must be disconnected.

R80A Bases Fixing Angle Tower Crane