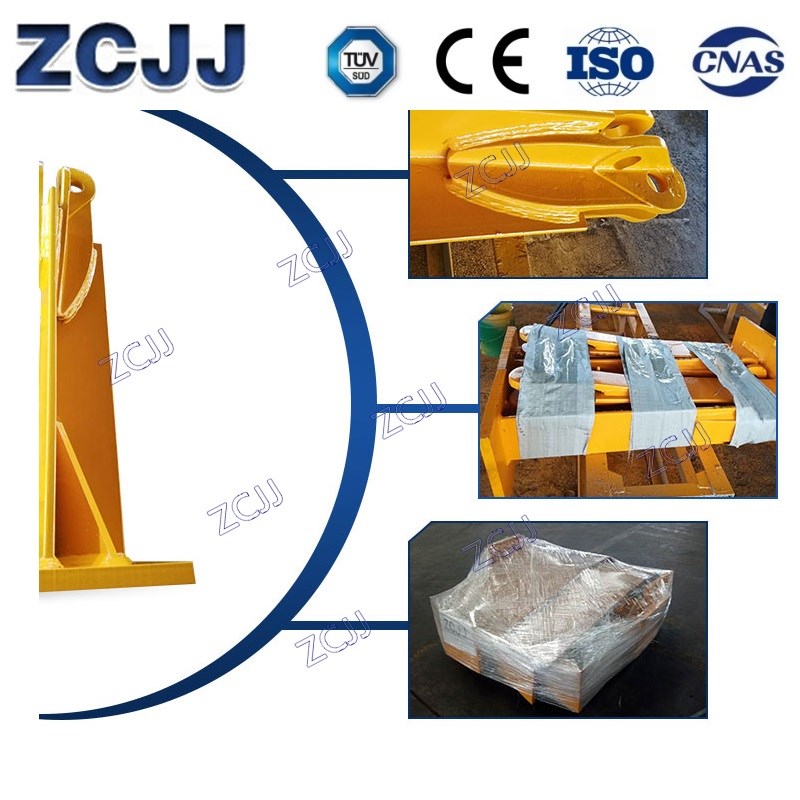

Bases Fixing Angles For S24D1 Mast

- ZCJJ

- China

- 5days

- 20sets

Cape Verde Tower Crane, Sierra Leone Tower Crane,

Products Specification

Type , Model: Bases Fixing Angles For S24D1 Mast

Size: 1.2M

Use for : S24A1 S24D1 S24D2 mast section , 1.2m L type mast

Materials: Q345B

Process: Blasting derusting,

Painting: Under painting , Middle painting, Surface painting.

Our factory produce and supply almost all famous brand tower crane :Mast section, Anchor Frame, Fixing angle ,Adaptor and so on as good quality and price.

Bases Fixing Angles For S24D1 Mast

Tower Crane Knowledge sharing:

Nine contents and requirements for regular maintenance of tower cranes

Regular maintenance of the tower crane is very important, and some necessary inspections should be done regularly. For serious cases, relevant personnel should be reported to stop service, repair or restricted use. The following are the contents and requirements that need regular inspections.

Bases Fixing Angles For S24D1 Mast

1. Monthly inspection and maintenance carry out inspection and maintenance according to the monthly inspection and maintenance items of tower cranes.

2. Verify the data and components of the tower crane: verify the signs and signage of the tower crane, and check whether the files of the tower crane are complete and effective. Whether the parts, accessories and spare parts are complete.

3. Brake: when the embedded depth of the riveting head of each brake shoe and brake belt piece of the tower crane is less than 0.5mm, the contact area shall not be less than 70%-80%, the brake wheel is out of circle or the surface mark is more than 0.5mm, the brake shall be round and wear, and the brake shall be dismantled, inspected and replaced if necessary.

4. Reduction gear box: remove the cover to clean the reduction gear box of each mechanism and check the tooth surface. If the tooth is broken, gnawed, cracked and the surface is peeling, it shall be dismantled, inspected and repaired.

Check the radial clearance of the gear shaft keys and bearings. If the gear keys are loose and the radial clearance exceeds 0.2mm, the bearings should be repaired, adjusted or replaced.

If the wheel shaft bending exceeds 02.mm, the bearings should be corrected. Check the ratchet pawl device, remove the shaft end leakage, replace the gear oil and add to the specified glaze. If the manufacturer has special requirements, it shall follow the manufacturer's instructions.

Bases Fixing Angles For S24D1 Mast

2. Open gear tooth clearance, bending the shaft and bushing wear: check the open gear, the tooth and is generally not more than the gear side clearance modulus of 0.2 to 0.3, tooth thickness and wear no greater than 20% of the tooth thickness.

Pitch circle theory wheel key must not loose kuang, each axle of bianjing chamfering without fatigue crack, shaft bending is less than 0.2 mm, sliding bearing radial clearance is generally not more than 0.4 mm, if you have questions should be repaired change.

6. Pulley block if the pulley groove wall is cracked or the groove wall is worn more than 20% of the original thickness, the rope cao radial wear is more than 20% of the wire rope diameter, and the pulley shaft neck is worn more than 2% of the original shaft neck, the pulley and pulley shaft shall be replaced.

7. Running wheel: if the contact surface between the running wheel and the track has serious cracking, peeling, surface and convex and concave grooves, it shall be repaired and replaced.

8. Metal structure of the whole machine: replace the welding, cracking and deforming parts of the steel structure. Replace damaged or corroded fastening bolts.

Repair and replace the damaged thimble ring, rope clip and fixed pin shaft of the fixed end of the wire rope.

9. Motor the motor rotor, stator insulation resistance when not less than 0.5 M Ω, can be in the running dry.

The burr on the surface of the copper head should be polished and smoothed, and the mica sheet of the copper head should be lower than the surface of the copper head 0.8-1mm.

Motor shaft bending exceeding 0.2mm shall be corrected. The rolling bearing shall be replaced when the radial clearance exceeds 0.15mm.

Bases Fixing Angles For S24D1 Mast