Bases Fixing Angles For M619A Mast

- ZCJJ

- China

- 5days

- 20sets

Jakarta Tower crane Surabaya Tower crane

Medan Tower crane Bandung Tower crane

Yogyakarta Tower crane

Sri Lanka Bay City Tower crane

Manila Tower crane Quezon City Tower crane

Cebu Tower crane Davao Tower crane

Dili Tower crane

Products Specification

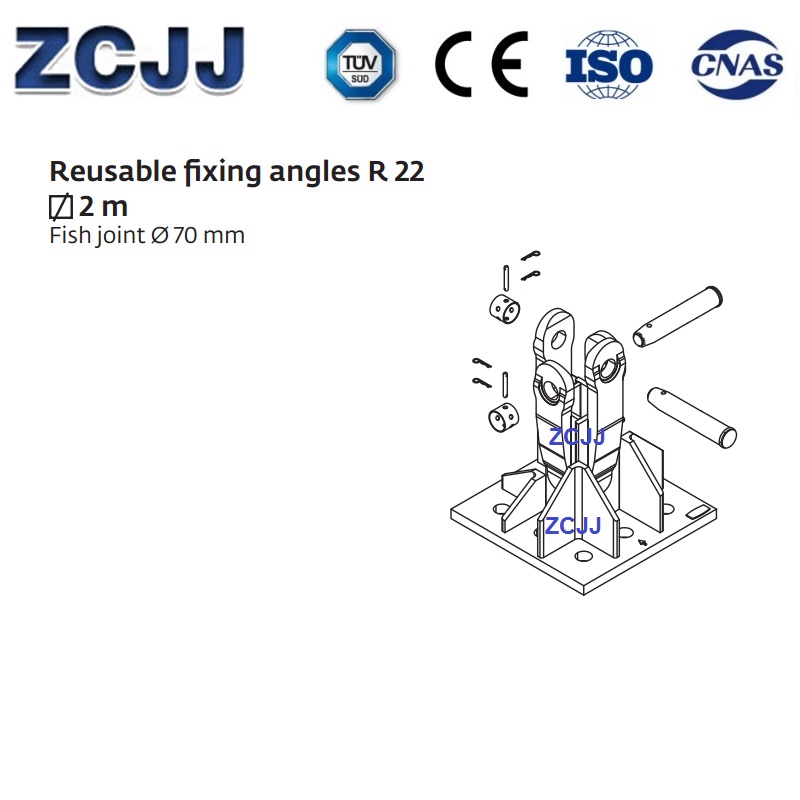

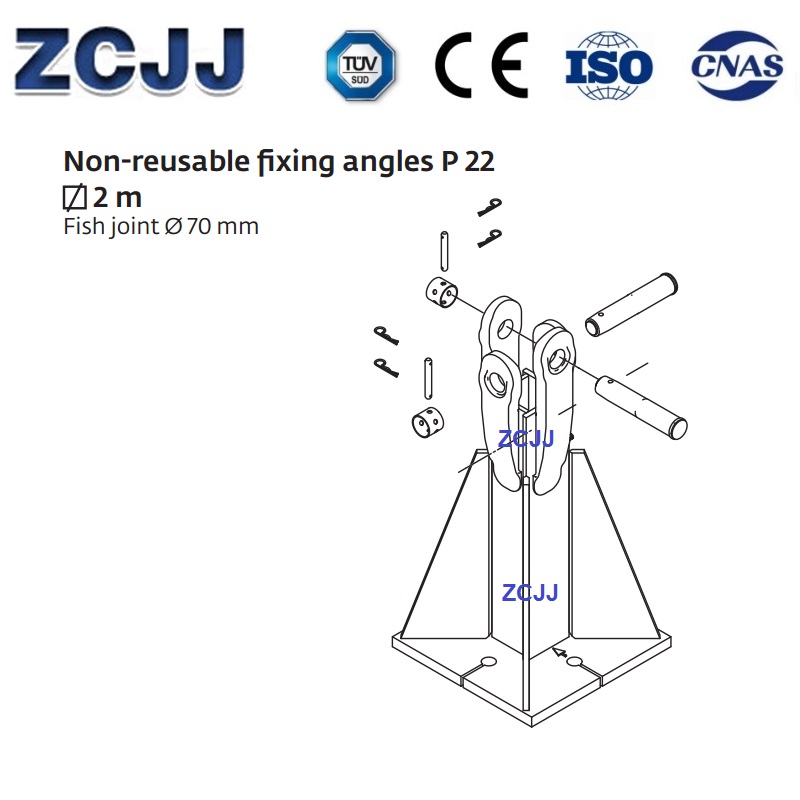

Type , Model: Bases Fixing Angles For M619A Mast

Size: 2M

Use for : M619A Mast M619C Mast ,2.13X2.13X5.32

Materials: Q345B

Process: Blasting derusting,

Painting: Under painting , Middle painting, Surface painting.

Our factory produce and supply almost all famous brand tower crane :Mast section, Anchor Frame, Fixing angle ,Adaptor and so on as good quality and price.

Bases Fixing Angles For M619A Mast

Tower Crane Knowledge sharing:

Safety technology for tower crane jacking: inspection of hydraulic system and jacking operation

In this paper mainly explains the safety technology of tower crane jacking operation: technical requirements of tower crane hydraulic system, operation process of tower crane jacking operation, safety precautions.

1. Hydraulic system of tower crane

(1) the hydraulic oil must conform to the variety and label specified in the original factory manual. In case of substitution, the performance must be the same or similar with the original variety, label, shall not be substituted at will, and shall not be mixed with two different varieties of hydraulic oil.

(2) must ensure the hydraulic oil and hydraulic system clean, no dust, water, metal chips and rust and other impurities. The amount of oil in the tank should be kept at the normal oil level.

Bases Fixing Angles For M619A Mast

The hydraulic system should be thoroughly cleaned when changing oil, and new oil must be filtered. Containers containing hydraulic fluid must be kept clean and the inner walls must not be painted.

(3) the hydraulic oil pipe joint shall be firmly shock-absorbent, and the hose shall not be sharply bent or twisted, and shall not touch or rub with other pipelines or objects.

(4) hydraulic pump inlet and outlet and rotation direction should be consistent with the sign. Do not knock the coupling when dismounting.

(5) the hose connection of the hydraulic cylinder shall not be loosened, the inlet and outlet of each valve shall not be installed in reverse, and the flange screws shall be tightened according to the specified pre-tightening force.

(6) when the hydraulic pump starts and stops, the relief valve shall be unloaded, and the adjustment pressure of the relief valve shall not exceed the maximum pressure of the hydraulic system.

Bases Fixing Angles For M619A Mast

(7) all parts of the hydraulic system must be reliable connection seal, no leakage, interlock device must be calibrated.

(8) when opening the vent valve or checking the leakage of the high-pressure system, do not face the direction of the nozzle.

(9) in case of minor or local discharge of the high-pressure system, the system shall be unloaded for maintenance and shall not be inspected or blocked by hands.

(10) in case of failure or accident of the hydraulic system, it must be unloaded before inspection and adjustment.

2. Tower crane jacking operation

(1) before jacking, it is necessary to check the connection of all parts of the hydraulic jacking system, adjust the gap between the guide roller of jacking jacket frame and the tower body, then release the cable, whose length is slightly larger than the jacking height, and tighten the cable reel.

(2) the jacking operation must be operated under the command of a special person. Non-operators are not allowed to board the operation platform of the jacking sleeve.

Only one person is allowed to operate in the operating room and strictly follow the signal command.

(3) jacking shall be carried out during the day, and sufficient lighting shall be provided when special conditions require night operation.

(4) no jacking operation shall be carried out when the wind force is above grade 4. If the wind suddenly increased in the operation, must immediately stop the operation, and make the upper and lower tower body connection firm.

Bases Fixing Angles For M619A Mast

(5) when jacking, the lifting boom and balancing arm must be in a state of balance, and the rotating part should be stopped.

Do not swing the jib or other work. If any fault is found in the jacking, the jacking must be stopped immediately for inspection, and the jacking can be continued only after the fault is removed.

If the failure cannot be removed within a short time, the jack jack shall be lowered to the original position and the connection bolts shall be tightened in time.

(6) when the connecting bolt (pin) between the rotary table and the standard section of the tower body is removed, if it is difficult to disassemble the last bolt, the bolt in the diagonal direction shall be re-inserted and other measures shall be taken.

The bolt shall not be loosened by rotating the lifting boom.

(7) during jacking, ensure that the jacking support foot is in place properly before proceeding to the next action.

(8) during jacking, pay attention to the pressure change of the hydraulic system at any time, and timely check and adjust if there is any abnormality. Someone should also have a theodolite to measure the vertical change of the tower body and record it.

(9) after jacking to the specified height, the tower must be attached to the building before jacking can continue.

(10) during the lifting process, the precautions shall be the same as above. However, the anchorage device must not be removed in advance, and can only be removed when the attachment joint is lowered.

Bases Fixing Angles For M619A Mast

(11) after the jacking for installation and disassembly, the connecting bolt pin shafts shall be tightened according to the pretightening force specified. The guide roller of jacking jacket frame is in good agreement with the tower body.

The left and right joysticks of the hydraulic system shall be in the middle position and the power supply of the hydraulic jacking mechanism shall be cut off.