Topkit 6Ton Tower Crane Hammer Head

- ZCJJ

- China

- 20 days

- 10units

Topkit tower crane is generally used in the construction site or the bridge site, through the big arm slewing and the trolley far and near to control the position of the hook, can lift the object in the turning radius. Compared with tower crane with tower head and tie rod, the model of hoisting arm force is simple and clear. Because there is no tower head, the installation height is low, which makes the installation faster and safer. Suitable for large buildings

Description Specification

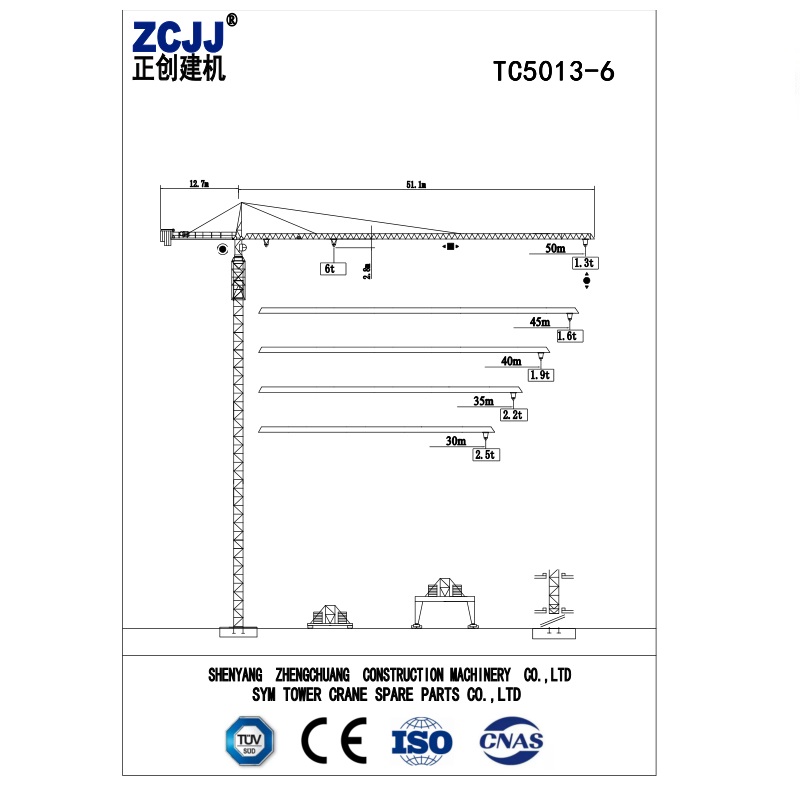

6Ton Hammer Head Topkit Tower Crane ,

Model: TC5013 ,

Jib length: 50m

Max load: 6Ton

Tip load: 1.3Ton

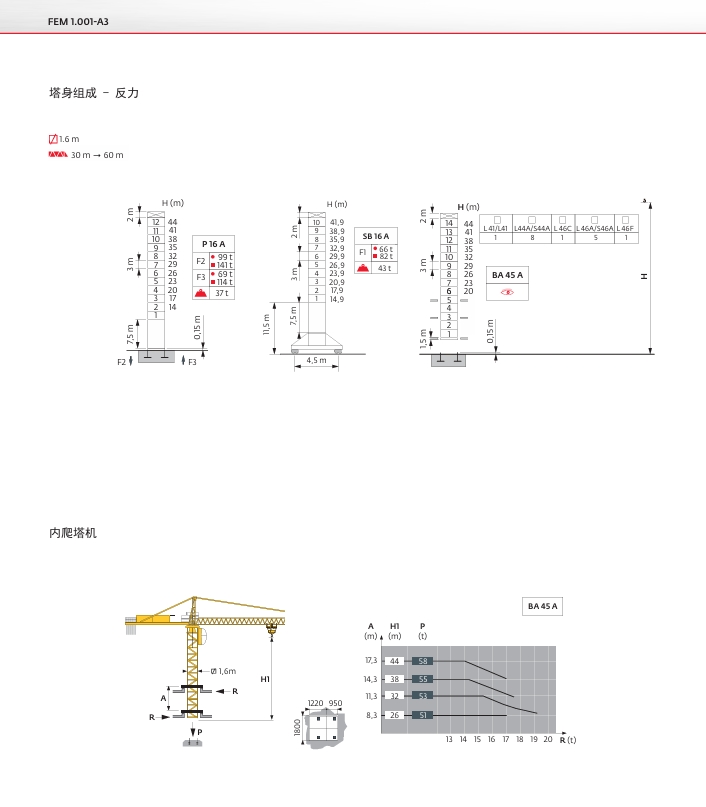

Mast type: 1.6m , L46A1 Mast Section, or QTZ mast : 1.5*1.5*2.5m

Type, Stationary , Inter Climbing , Travelling.

Topkit 6Ton Tower Crane

Tower Crane Knowledge sharing:

This paper mainly introduces the safe operation rules of the lower tower crane: machinery, personnel, environment, operation and other requirements

(1) tower crane foundation soil bearing capacity must be used strictly in accordance with the original factory rules or meet.

(2) the track foundation or concrete foundation of tower crane must be checked and calculated through design, and can only be used after passing the acceptance inspection. Slope and drainage facilities shall be built around the foundation, and a certain safety distance shall be kept from the foundation pit.

(3) the demolition and installation of tower cranes must be carried out by a professional team that has obtained the qualification certificate for the demolition and installation issued by the construction administrative department.

(4) disassembling and assembling personnel shall wear safety protection articles, fasten safety belt when working in height, and be familiar with and earnestly implement disassembling and assembling process and operating procedures.

(5) after the installation of the tower crane, technical inspection and adjustment of the whole machine shall be carried out. Only after passing the inspection in stages and the whole machine, can the crane be delivered for use. In the case of no load, the vertical deviation between the tower and the ground shall not exceed 4/1000. The motor and hydraulic device of the tower crane shall be in accordance with the relevant provisions on the motor and hydraulic device.

Topkit 6Ton Tower Crane

(6) jacking, installation and disassembly shall not be carried out when the wind force reaches grade 4 or above. Before jacking, check the connection of each part of hydraulic jacking system. Do not turn the boom or other work when jacking.

(7) in case of gale-force 6 or above, heavy rain, snow, fog and other bad weather, the tower crane shall stop working in the open air. After the rain and snow or rain and snow in the operation, should first pass the test, confirm that the brake is sensitive and reliable before the operation.

(8) tower crane metal structure, track and all electrical equipment metal shell should be reliable grounding device, grounding resistance should not be greater than 4 , and should set up a lightning protection device.

(9) the strut arrangement, mutual spacing and distance between walls of each attachment device shall be in accordance with the provisions of the original factory, and the self-made strut shall have a design calculation book.

(10) tower cranes shall not be operated close to overhead transmission lines, and safety protection measures shall be taken when they must be operated online by the roadside due to limited on-site conditions. The safe distance between tower cranes and overhead transmission wires shall comply with the provisions.

(11) before the operation, it is necessary to have a comprehensive understanding of the surrounding environment of the work site, driving roads, overhead wires, buildings and the weight and distribution of components.

Hammer Head Tower Crane

(12) when the tower crane is in operation, there shall be sufficient working site, and there shall be no obstacles in the lifting boom and turning radius of the tower crane.

(13) before the tower crane slalom, amplitude change, walking and lifting of the hook, the operator shall sound. before power transmission start control switch should be at zero, turn on the power, check the metal structure part no leakage before the machine.

(14) if the tower crane far away from the ground in the control room has difficulties in normal command, two command personnel at high altitude and on the ground can be set, or the effective contact method such as intercom can be used for command.

(15) safety protection devices such as amplitude limiter, travel limiter, moment limiter, hook height limiter and all kinds of travel limit switches of tower cranes must be complete, sensitive and reliable, and shall not be adjusted or dismantled at will. It is forbidden to replace the control mechanism with limit device.

Hammer Head Tower Crane

(16) the command personnel of tower cranes must hold a certificate and work closely with the operators. Operators must also hold a license to work, the operation should strictly execute the command of the signal, such as the signal is not clear or wrong, the operator should refuse to implement. If an accident is caused by a command error, the command personnel shall be held responsible.

(17) when the tower crane is in operation, no one is allowed to stay, work or pass under the lifting boom and the weight. When lifting heavy objects, it is strictly forbidden to pass over people. It is strictly prohibited to carry people by tower cranes.

(18) tower crane machinery must be operated in accordance with the prescribed lifting performance of tower cranes, and objects of unknown weight shall not be lifted under excessive load. Under special circumstances, when the over-load is needed to be used, it must be checked and calculated, there must be technical measures to ensure safety, approved by the technical person in charge of the enterprise, and there must be a special person on site to supervise the lifting, but the lifting shall not exceed 10% of the load limit.

(19) the lifting and landing speed of heavy objects should be even, and no quick, slow or sudden braking is allowed. Turn left and right to be stable, when the rotation did not stop before the reverse action must not be made. Non - gravity drop tower crane, do not drop freely with load.

(20) the minimum distance from the top of the tower crane hook device to the bottom of the trolley frame 1000mm for the upper rotary type 2 times, 700mm for the 4 times; It is 800mm for the down turn type 2 multiplier. When the multiplier is 400mm, the lifting shall stop immediately.

(21) during operation, when the operator leaves the operation room temporarily, the power must be cut off and the rail clamping device must be locked. After the completion of the work, the tower crane should be parked in the middle of the track, the lifting boom should be turned downwind direction, and loosen the rotary brake, the car and balance weight should be placed in the non-working state.

(22) it is strictly prohibited to lift heavy objects and hang them in the air for a long time. In case of sudden failure during operation, measures shall be taken to land the heavy objects in a safe place, and the motor shall be shut down or the power shall be cut off for maintenance. In case of sudden power failure, all controllers should be immediately set to zero, disconnect the main power switch, and take measures to reduce the weight to the ground safely.

(23) it is strictly prohibited to use tower cranes to pull, lift or lift heavy objects buried underground or congealed on the ground. The concrete components or formwork cast on site must be all loose before lifting.

(24) when lifting heavy objects, tie them firmly and steadily. Do not pile or hang any loose objects on the heavy objects. Sporadic materials and objects, must be hung with a cage or wire rope binding firm, before lifting. Objects marked with the lashing position or mark shall be lapped according to the indicated position.

(25) when the lifting load reaches 90% or more of the rated lifting weight of the tower crane,stability of the crane, reliability of the brake, stability of the heavy object and firmness of binding. Confirm and then continue to lift. For heavy objects that may wobble, a pull rope must be used.