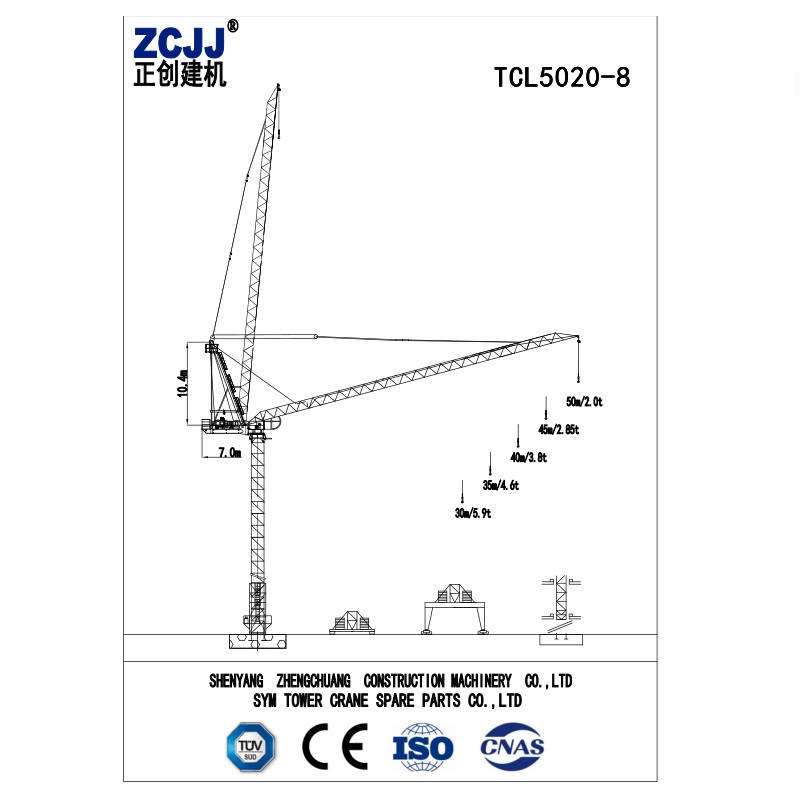

Luffing Jib 8Ton Tower Crane

- ZCJJ

- China

- Stock

- 5 units

Luffing jib tower crane the large elevation Angle of the lifting arm is equivalent to the increase of the height of the tower body, and the effective extension of the working range is almost the semi-sphere space with the length of the lifting arm as the radius.

Description Specification

8Ton Luffing jib Tower Crane ,

Model:TCL5020 ,8Ton

Jib length: 50m

Max load: 8Ton

Tip load:2.0Ton

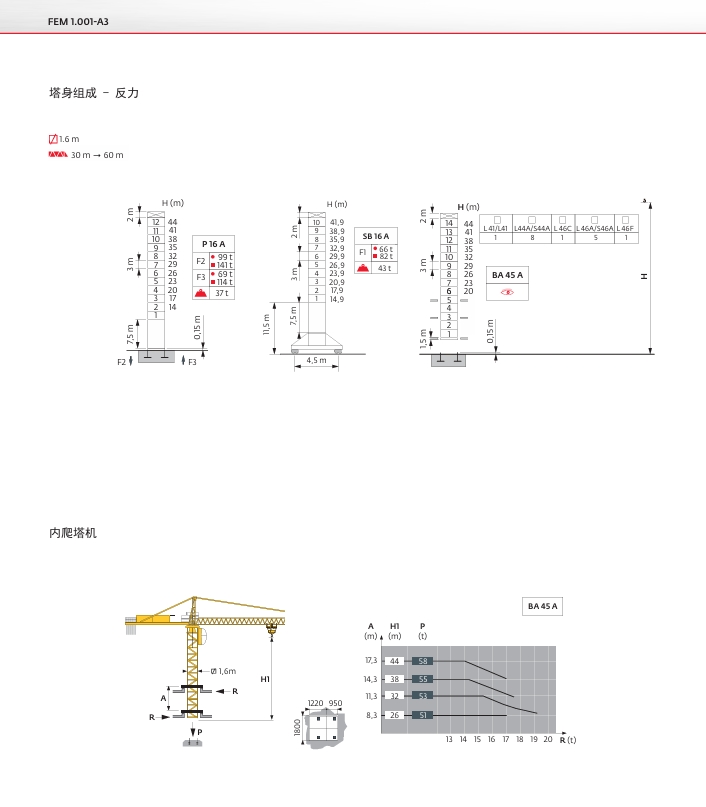

Mast type: 2m , L68A1 Mast Section, AND 1.6m , L46A1 Mast Section

Type, Stationary , Inter Climbing , Travelling.

8Ton Luffing jib Tower Crane ,

Tower Crane Knowledge sharing:

Application of practical experience, the rapid elimination of the tower crane electrical fault

Practical experience - fast way to eliminate electrical fault of tower crane

(1) to determine the electrical fault location by inquiring segmentation method

That is to ask the field control personnel, understand the general control system, lifting system, rotary system, amplitude conversion system, cart walking system and other parts of the operation, distinguish between the primary and secondary, remove part of the doubt, find out the possible fault system.

8Ton Luffing jib Tower Crane ,

(2) eliminate obvious electrical faults by observation, elastic pressure and percussion

The method is as follows: open the electric cabinet, first check whether there is any obvious damage to the electrical appliances, charred and loose wiring and other signs; Then check the sensitivity of contactor armature, various travel limit switches on the wheel, start brake button, etc.

If it is confirmed that everything is normal, a rubber hammer can be used to knock the working components, especially the moving parts, under the condition that the tower crane is energized. If the circuit fault suddenly disappears, it indicates that there is a phenomenon of poor contact near the striking components or by the striking components themselves, it should be eliminated immediately.

(3) use short connection method and component replacement method to quickly eliminate electrical faults

In other words, according to the electrical schematic diagram, the suspicious circuit part is successively shortened to verify whether other parts of the system are normal. If the other parts are normal, the fault exists in the components of the short connection part. At this time, the same components in other systems in the main control cabinet can be removed and replaced with components suspected to be faulty. If the fault is removed, it means that the replaced components have been damaged.

Type a QTZ80 tower crane, for example, light load lifting when everything is normal, overloading, Ⅱ, Ⅳ block I also normal, but no Ⅲ block, because of the heavy lifting in the process of from (I) block at low speed to high speed (Ⅳ block) no transition (Ⅲ block), tower crane with speed impact is very big, shaking the tower, affect human safety, must be ruled out.

Then first open the main control cabinet, find the lifting system, check the appearance, did not find obvious damage, burning and loose wiring phenomenon. Because when I, Ⅱ block is normal, the eddy current (YBHE) and KHl should be normal

When the tower crane overloading by I, Ⅱ gets Ⅲ block, main control cabinet of the contactor and time relay KHE, KTH1, KHU, KHB, KTH2, KHJ, KHL, KTH3, KHL, KTH5, KH2, KTH6, KH3 all actions, in turn, but did not change significantly lifting speed.

8Ton Luffing jib Tower Crane ,