Luffing Jib 6Ton Tower Crane

- ZCJJ

- China

- Stock

- 4 units

Luffing jib tower crane,This is of great significance for the construction of the main structure and the hoisting of the towering components on the main structure.

The tail turning radius is between 8 and 11 meters, which provides more options for tower group operation and construction in narrow urban working space, and is even the only choice for construction of super high-rise buildings in the central area of the city.

But on the other hand, due to the lifting boom fluctuation caused two problems. First, the gravity bending distance of the boom changes greatly

6Ton to 12Ton Luffing jib is our main products.

Description Specification

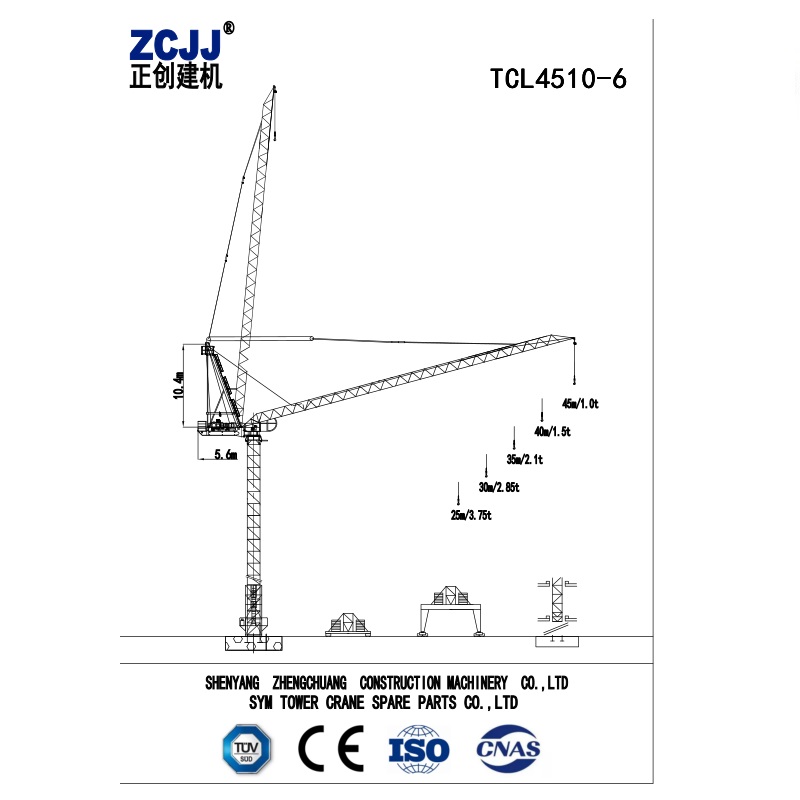

6Ton Luffing jib Tower Crane ,

Model:TCL4510 ,6Ton

Jib length: 45m

Max load: 6Ton

Tip load: 1.0Ton

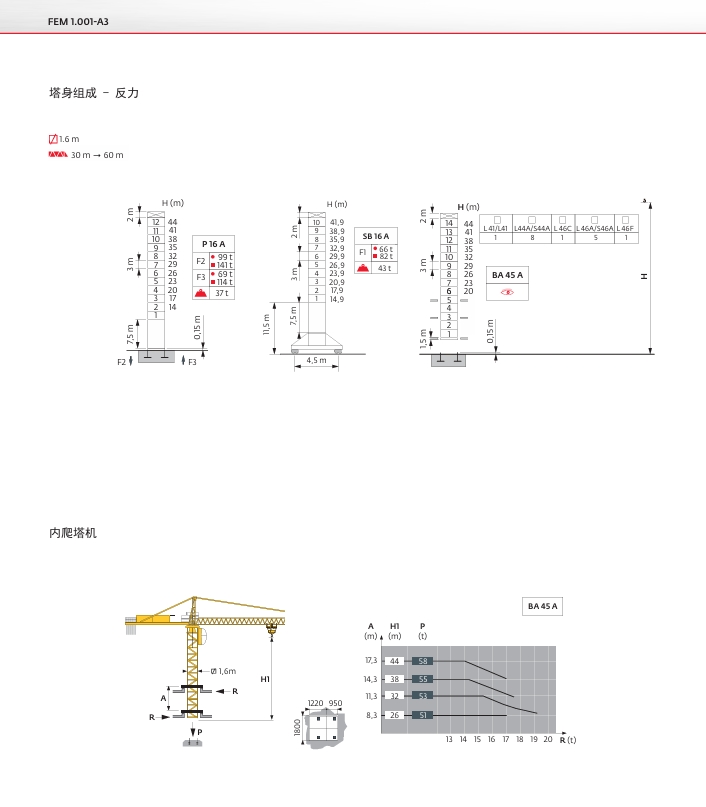

Mast type: 1.6m , L46A1 Mast Section

Type, Stationary , Inter Climbing , Travelling.

Description Specification

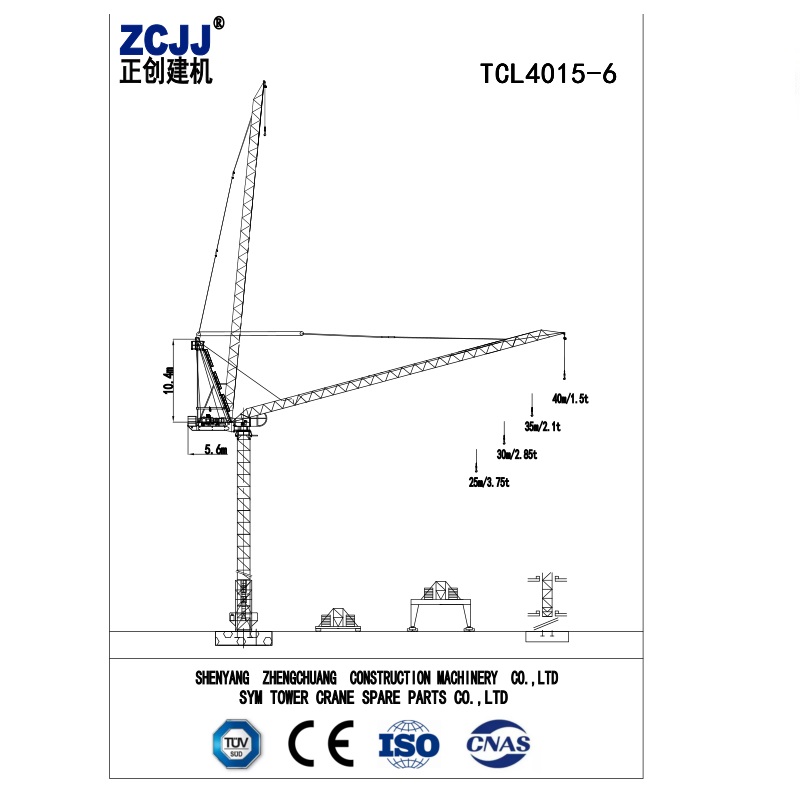

6Ton Luffing jib Tower Crane ,

Model:TCL4015 ,6Ton

Jib length: 40m

Max load: 6Ton

Tip load: 1.5Ton

Mast type: 1.6m , L46A1 Mast Section

Type, Stationary , Inter Climbing , Travelling.

6Ton Luffing jib Tower Crane ,

Tower Crane Knowledge sharing:

The common practice of the foundation of the tower crane and the foundation of the rail type tower crane

The common practice of the foundation of the rail-type tower crane is: first, the foundation shall be rammed or a layer of 3:7 lime soil cushion shall be made, then the gravel track slag shall be laid, and then the wooden sleeper shall be placed, and the steel rail shall be laid on the wooden sleeper. This kind of practice consumes large amount of wood and has short service life, which is not suitable for heavy tower crane.

6Ton Luffing jib Tower Crane ,

The recommended practice today is to erect a reinforced concrete floor or a reinforced concrete sleeper beam on a rammed foundation, install the i-beam on the floor or sleeper beam with embedded parts, and then install the rail on the i-beam.

In order to improve the efficiency of rail laying and save the cost of rail laying, the reinforced concrete sleeper beam, i-beam and rail are usually assembled together to form a 12.5m long prefabricated reinforced concrete rail foundation. This track foundation is very suitable for heavy lift tower cranes . The bottom frame fixed jack-up tower crane is most suitable to use block type reinforced concrete foundation.

6Ton Luffing jib Tower Crane ,

On the foundation with high ground endurance, and the top and bottom of the plate should be reinforced in both directions. If the tower crane must be installed near the deep foundation pit, the cast-in-place pile cap foundation shall be adopted to ensure the solidness and stability of the tower crane foundation, and measures shall be taken to prevent the foundation pit slope from collapsing.

The foundation of the tower body fixed self-rising tower crane must meet two requirements

First, the upper load of the tower crane is uniformly transferred to the foundation and the ground bearing capacity shall not be exceeded;

The second is to make the tower crane in all kinds of adverse working conditions can maintain the overall stability without tipping.

Therefore, this kind of tower crane foundation volume is quite huge, the foundation weight must be equal to the tower crane weight. The foundation weight of the fixed tower crane is closely related to the free height of the tower crane. If the tower crane needs to be erected near the deep foundation pit in the foundation construction stage, and the surface soil condition is poor, the foundation must be supported by bored piles.

6Ton Luffing jib Tower Crane ,

Therefore, in order to save the cost of foundation construction, it is advisable to decompose the whole mass concrete foundation into a number of precast concrete blocks to form an assembled reinforced concrete foundation, so as to achieve repeated use for many times and minimize the cost of tower crane foundation decomposed into each project.